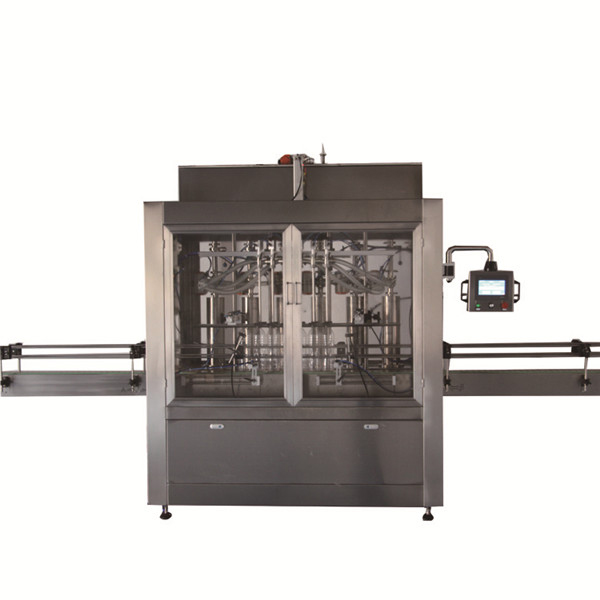

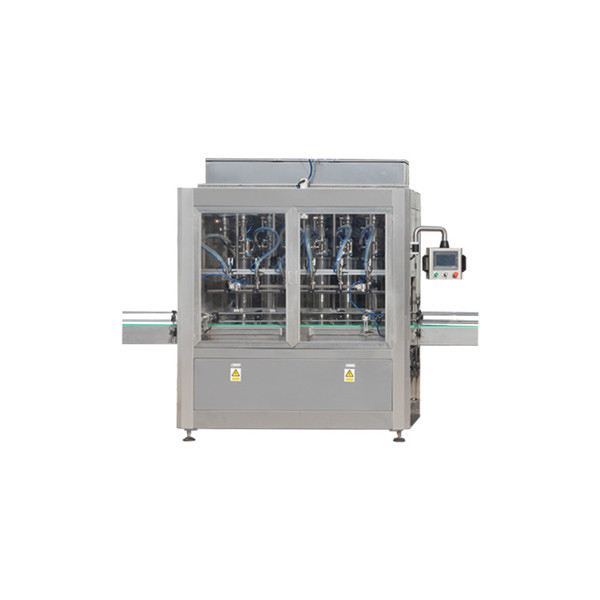

Automatic Liquid Filling Machine

Automatic Liquid filling machines are an excellent way for businesses to improve the efficiency and effectiveness of packaging liquid products. These machines increase the speed and accuracy of filling containers and bottles, which in turn saves a business time and money.

Fully automated systems are for high speed applications and include conveyors and electro/pneumatic PLC controls.

They are suitable for almost any liquid including viscous liquids containing particles such as foods, and can cater for containers in the 5ml to 5 litre fill range. Outputs range from 20 – 120 bottles per minute (1200-7200/hour).

What Are Liquid Filling Machines?

Liquid fillers help transport a liquid product from a holding tank to a container or bottle. Manual filling machines are hand operated, while automatic filling machines don’t require an operator to be present for each individual fill. By using an automatic filling machine, a business can expect the following benefits to their packaging process.

Automatic Liquid Bottle Filling Machine works on volumetric principle with syringe & piston & nozzle. It is used to fill liquid in bottle in pharmacy, food, dairy, agro chemicals and Beverages industries.

The unit is made compact, versatile and enclosed in stainless steel elegantly matt finish body, consists of S.S. Slat Conveyor, Drives unit with syringe & piston, Reciprocating Nozzle with self-centering devices & No container No filling system arrangement is standard features of the machine. The main drive of the machine and conveyor drive consist of gear motor with synchronized variable drive.

Containers moving on S.S.304 Slat conveyor from turn table or washing machine, feed below the filling nozzles through a settable twin pneumatically operated stopper system. The twin pneumatically operated stopper system and reciprocating nozzles can precisely match for centering of container below nozzles, to avoid spillage of liquid on container. Liquid suck by syringe & piston assembly and fill in bottle through nozzle. Filling doze can be adjustable by eccentric drive block. To minimize foaming adjustable nozzle will reciprocate according to filling dose, nozzle will go upwards slowly from bottom level of bottle towards neck during filling.

Benefits Of Using Automatic Liquid Filling Machines

The first benefit of using automatic filling machines is that they are reliable and consistent in filling containers with the correct amount. Compared to pouring liquid by hand, the automatic filling machine will accurately fill a container on a steady basis.

Secondly, automatic filling machines are faster than manual pouring. At a certain production amount, it becomes impractical and too costly to hire manual labor to pour liquid into each bottle.

Lastly, automatic filling machines help increase the capacity of orders that a company can fulfill. When compared with manual pouring, automatic filling machines help a company keep up with their customers demand by lifting their output.

Straight-line or inline filling machines are among Filling Equipment’s most popular and widely-used types of fillers. We offer automatic filling machine systems to suit varying industry needs. These fillers are a good start to gradually automate your production line and meet an ever-increasing demand for your products.

Straight-line filling machines ferry and fill multiple bottles in a straight line. For automatic systems, the user sets the configuration for the machine, in terms of the amount of the filling product per container. Semi-automatic ones, however, require more human application to control the amount of product that goes into the bottle, jar, or can.

Accuracy is something to consider when looking for a automatic filling machine. accuracy can be measured by the configuration it carries: volumetric or liquid level. A volumetric setting is more precise and ideal for products that need to be in exact amounts. However, many choose a liquid level setting because it is low-cost and efficient.

Most liquid products use a liquid level setting, to ensure that containers are filled with just the right amount. Filling Equipment’s wide array of straight-line filling machines guarantees accuracy in the process, so that you don’t have to worry about filling the entire container. This also ensures the satisfaction of your customers when they purchase one or any of your products.

If you want to increase the accuracy and efficiency of your filling process, consider our automatic filling systems. While not as fast as our more advanced filling systems, they’re efficient enough to meet industry requirements, especially those who are just starting to modernize their production lines. A straight-line filling machine is a great way to increase your output in order to expand into a bigger market in the future.

All workmanship, on both our liquid nozzles and our machines is guaranteed.

Automatic filling machines dramatically increase the amount of liquid products that a company can package within a given time period. They are faster, reliable and more consistent in filling liquid into containers, when compared to manual pouring. Whether your business works with food and beverage, pharmaceuticals, cosmetics, or chemicals, they can all benefit from using the automatic filling machine to package their products.