Small Liquid Filling Machine

VKPAK manufactures a range of standard liquid filling machines to suit a wide variety of liquids, bottle sizes and production outputs. For businesses ranging from SME’s through to large multinationals, our machines can be used for a wide spectrum of applications.

Liquid fillers, in general, aren’t built the same way. Even though one type of filler has more advantages over another type, a machine’s efficiency should not be the only factor to consider when getting one. The cost of purchasing and operating these filling machines must be taken into account, as well as their design and construction. VKPAK designs different types of filler liquid machines sold at reasonable prices to help meet different needs and demands.

We build in-line, straight line,rotary and piston-type liquid filling machines for handling from very small to high volume filling, manual to fully automated. All workmanship on our machines is guaranteed.

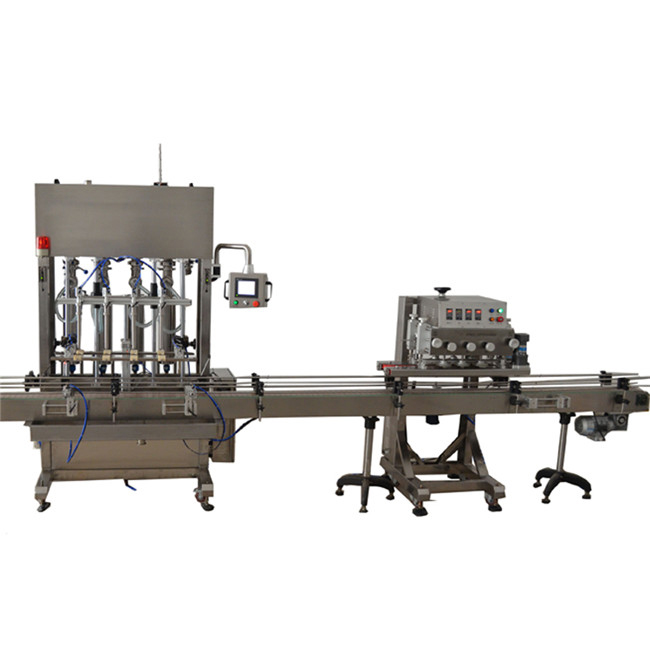

Automatic Straight Line Liquid Fillers

The advent of automation introduced accuracy and speed of production with less intervention from humans. Our automatic straight line liquid fillers adopt the principles of automation with its easy-to-use controls. With the push of a button or two, the machine can proceed filling bottles at a preset value. By reducing the human factor to setting the controls, containers can be filled and capped more accurately and quickly.

His liquid filler is definitely a step up from its semi-automatic counterpart. Benefits include production efficiency using less manpower, hence, reduced cost of labor.

Automatic Rotary Liquid Fillers

Rotary liquid fillers are designed for manufacturers whose demand for their products exceed the output of the straight-line fillers. These machines have larger heads and a faster rate of production, allowing these to fill more containers per unit of time. Often, rotary fillers are part of a dual-modal or tri-modal production line where various bottling processes are integrated.

You often see this type of filling machine inside major bottling facilities due to their rate of production. The line of bottles preceding the filler is an endless stream, ensuring uninterrupted production.

Piston Fillers

Piston fillers, although slower than other fillers, are perfect for products with a thick consistency (e.g. peanut butter, cream cheese, pastes, etc.). The force applied by a powerful piston can displace enough of the product into the container.

Piston filling machines can either use a check valve for free-flowing fluids such as water or juice, or a rotary valve for the thick ones.