Oil Filling Machine

Whether you are in the market for an automatic or semi-automatic oil filling machine, it’s important to note they are not much different from other machines. Filling machines work on the same basic principle, whether you are in need of a liquid filler for soap or an oil bottle filling machine. Our goal is to ensure no matter what type of liquid is inside, your machines are able to hold up to the pressure placed upon them. When in need of an auto oil filling machine or any other type of oil filling machine, we want to be the first name you think of due to our extensive line of machines and parts for whatever you need.

Oil Filling Machine Suppliers

At VKPAK, we are dedicated to ensuring all our equipment, whether its auto oil filling machines or semi-automatic oil filling machines, are up to the standards our customers want and expect. We carefully design and test each machine to ensure maximum productivity and protection when it’s being put to use. This is our way of staying on top as one of the most sought after oil filling machine suppliers in the area. By providing companies with what they need, we have the ability to stay on top of our game and provide quality oil filling machines.

A Complete Range For Bottling Food Oil (Olive Oil, Seed Oils, Etc)

VKPAK has designed various solutions for bottling oil, and capping and labelling the bottles, entirely automatically.

Customers are sure to find the ideal oil bottling solution for their needs in the wide range of machines available, from small systems also ideal for co-packing, to medium and large oil bottling lines used by major national and international producers.

Quality And Experience

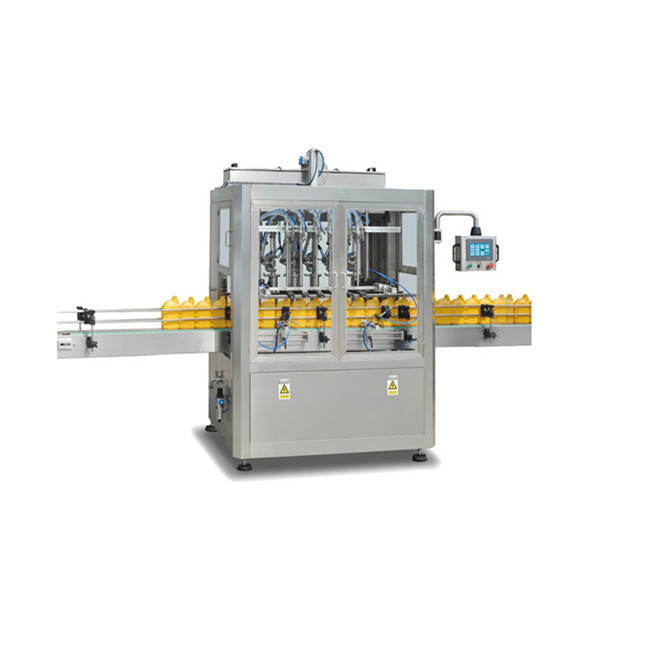

The high reliability of the oil filling machine made by VKPAK, their high production capacity, simple operating demands, and rapid size changeovers, are just some of the features that have made VKPAK one of the top manufacturers of bottling lines in the world.

Its capacity for innovation and superior flexibility are the ideal combination for the production of oil bottling lines that adapt perfectly to the needs of its customers for filling either traditional bottles (glass or PET) or lines for filling small bottles. The VKPAK range also includes a Monobloc for filling and capping metal tins.

The lines are engineered, produced and assembled in Italy for the guarantee of superior standards of quality. Each oil filling machine made by VKPAK can be customised to meet specific demands of its customers.

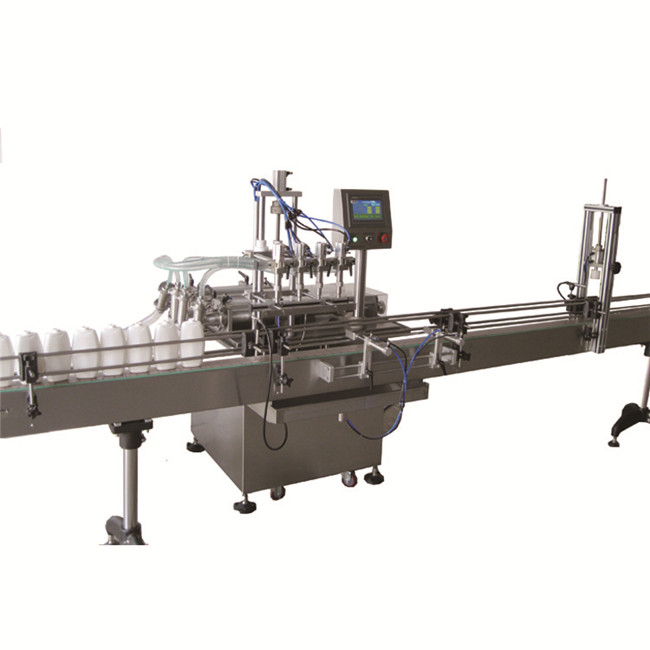

Consumable oil products such as coconut and peanut oils require different types of edible oil filling equipment based on their thickness. VKPAK carries plenty of liquid packaging machines intended for packaging edible oils and many other water-thin to more viscous liquid products. We offer a variety of filling machines along with other equipment such as conveyors, cappers, and labelers to form a complete packaging assembly that offers consistent efficiency.

Install A System Of Oil Filling Equipment

Vegetable oils and other consumable oil products can vary in viscosity, which means that different edible oil filling machines are required depending on the application. To meet the needs of various edible oil production lines, we offer piston, gravity, overflow, pressure, and pump fillers to keep the filling process accurate and efficient.

To complete the packaging process, we offer a selection of other liquid packaging machinery that’s compatible with consumable oil products, including customizable systems of bottle cleaners, conveyors, labelers, and cappers. Each machine in our inventory is designed to maximize productivity in packaging facilities.

Use High-Quality Oil Filling Machines With Many Configurations

Like other types of packaging systems, you can fully customize cooking oil filling machines and other edible oil machines based on the needs of your specific application. Specifications may be based on the viscosity of the product and space requirements in the facility, all of which VKPAK can meet. Our reliable food oil machines can help keep your facility efficient while making sure your production lines are as profitable as they can be. No part of your food oil packing systems will remain overlooked with a full system installed to keep your operations optimal.

Incorporating Complete Oil Filling Machine Systems

If you want more than oil filling equipment installed in your production line, we have the equipment you need to make your entire assembly more reliable.

Before the filling process, our bottle cleaners can make sure that containers are free of any potential contaminants including harmful bacteria. After filling equipment accurately fills containers, capping machines can attach airtight caps of different shapes and sizes to custom-sized bottles, and labelers can place high-quality labels containing images and text that display product information and brands. A system of conveyors transports products between stations at consistent speeds, making sure each product is filled and packaged within the designated amount of time for maximum profitability.

Get A Custom Oil Packaging System Design At VKPAK

To meet your application’s specific needs regarding space requirements and product specifications, we can help with the design of a complete packaging system for your facility. To make sure that equipment is implemented properly in your facility, we also offer installation services.

Our technical experts are also capable of maximizing the effectiveness of your packaging system by providing field service, high-speed camera services, and leasing. Each of these services can improve the overall performance of your machinery along with operator productivity.

If you would like to get started on the design and setup of a complete system of oil filling equipment and other packaging machines, contact VKPAK for immediate assistance.