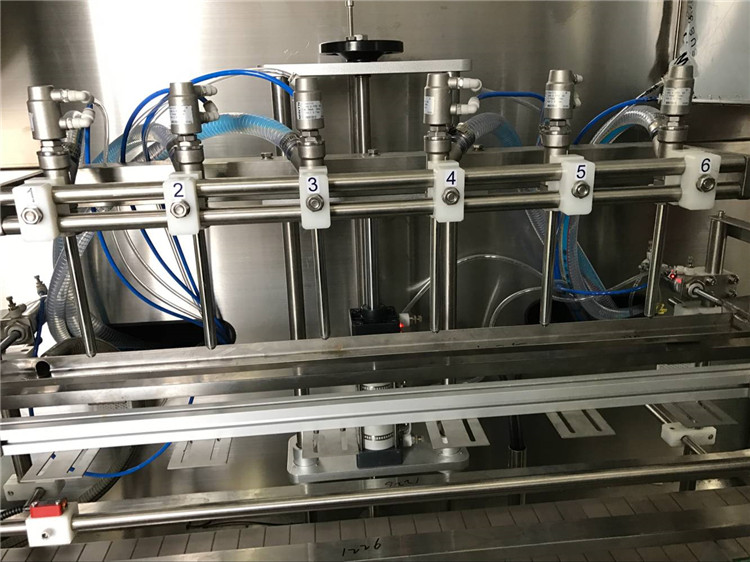

Equipment Brief Introduction:

This production line includes: a 4 head piston filling machine, a capping machine, an aluminum foil sealing machine, a 10w laser marking machine, a laser marking machine, a semi automatic carton sealing machine, a two face labeling machine ;

The machine type, number of machines, speed, capacity, size, etc. Of the production line can be customized according to the customer's production needs; we can develop a professional integrated filling and packaging production line plan for the customer.

This automatic filling line can be customized to fill various products,such as : automotive glass cleaner, lubricating oil, engine oil, etc.

| Parameters of 4 Head Piston Filling Machine | |

| Filling head quantity | 4 |

| Filling volume | 500ml-5000ml |

| Filling way | Piston drives multiple nozzle filling |

| Filling speed | 240BPH for 5L |

| Filling precision | ±1% |

| Program control | PLC + touch screen |

| Filling nozzle, parts connected with liquid | 316#, PVC |

| Air pressure | 0.6-0.8MPa |

| Conveyor | 152mm POM chain belt, H:750mm±25mm |

| Conveyor motor | 370W frequency motor |

| Power | 2KW, 380V, three phase five wire |

| Protection | Alarm and stop when lack of liquid |

Capping Machine

| Parameters of Capping Machine | |

| Cap Distributor Way | Lift |

| Suitable specifications | According to customer samples |

| Capping Way | Claw fetch and pneumatic capping |

| Capacity | >240BPH(5L) |

| Power | 500W, 220V |

Aluminum Foil Sealing Machine

| Parameters of Aluminum Foil Sealing Machine | |

| Suitable Bottles | According to customer samples |

| Sealing wire | Plane formula |

| Capacity | >240BPH |

| Power | 220V, 4400W |

| Converter | Schneider |

| Cool way | Air |

Laser Marking Machine

| Laser Marking Machine Configuration | |

| Laser marking nozzle | beam expander 1064-3 Japan |

| High velocity scanning galvanometer | SUNINE-10 |

| Galvanometer drive card | SUNINE-102 NJ1064-12XY |

| Field lens | Japan NJ-110 |

| Laser | American 10W |

| Laser marking holder | Two dimensional support |

| Computer and software control system | 7 inch touch screen LG |

| Marking software system | CE2.1 |

| Working table | Three dimensional adjustable |

| Power switch | Taiwan 350-27W |

Semiautomatic Carton Sealing Machine

| Parameters of Semiautomatic Carton Sealing Machine | |

| Delivery speed | 0-20m/min |

| Max packing size | 600*500*500mm(L*W*H) |

| Min packing size | 200*150*150mm(L*W*H) |

| Power | 380V, 50Hz, 400W |

| Suitable tape | 48mm, 60mm, 75mm |

| Machine dimension | 1770*850*1520mm(L*W*H) |

Two Face Labeling Machine

| Parameters of Two Face Labeling Machine | |

| Suitable label position | one or two face of square bottle |

| Suitable product | W: 20-110mm, L: 40-200m, H: 50-400mm |

| Suitable label range | W: 20-200mm, L: 20-200mm |

| Capacity | 60-200BPM |

| Labeling precision | Flat: ±1mm,Cambered surface : ±1.5mm |

| Power | 220V, 2KW |

| Conveyor | 152mm POM chain belt, 0-30m/min, H: 750mm±25mm |

Our Services

Packaging & Shipping

The delivery time of a production line is generally 60 days; the single product is about 15-30 days;

The product can be assembled or disassembled and packaged according to customer requirements;

Products are generally wrapped in foam paper and wooden boxes.

FAQ

Q: What industry is your product suitable for?

A:The product line we develop and produce is suitable for the production of various, liquid, paste, powder, solid products. The specific product materials, functions, specifications and production capacity can be customized according to customers' products and requirements.

Q: What if the machine fails during use?

A:Our products will be carefully inspected and ensured before delivery, and we will provide the correct instructions for use of the products; in addition, our products support lifetime warranty warranty service, if there are any questions during the use of the product, please consult our work. personnel.

Q: When can I get my machine after paid?

A: The delivery time of a production line is generally 60 days; the product is about 15-30 days.We will deliver it on time as the date we agreed both side.

Q: How can I install my machine when it arrives?

A: We will provide installation videos and tutorials, or send our engineer to your side ASAP you get all your machines ready , for testing and teaching your technicians how to run the machines.

Q: What payment do you accept?

A: We generally use T/T or L/C, and we can negotiate the payment method.