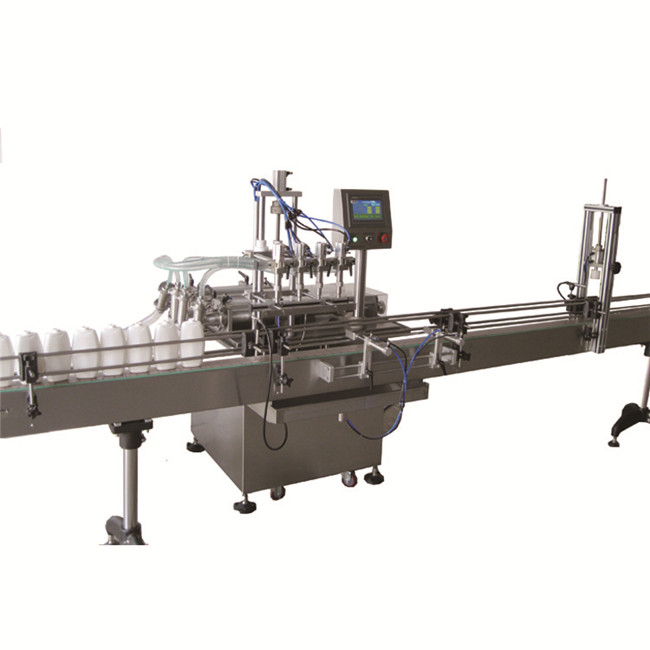

Product Name: Automatic Filling Machine

<1> Configuration:France Sinde PLC, Schneider intelligent touch screen, Schneider low-voltage control, Taiwan Yade passenger pneumatic components.

<2>Characteristics: 100ML-5L bottled special filling machine for lubricating oil, 6-10 rows filling at the same time.

The upper weighing pump type pressurized double-speed filling has the advantages of fast filling speed, high filling precision and more stable operation. Each pipe connection point is installed with a quick connector, which is convenient and quick to clean and replace parts.

The anti-drip and anti-drawing filling nozzle ensures that the oil does not draw water and drip.

The whole machine is equipped with a cleaning function, and a special cleaning tank is provided at random, which makes it more time-saving to change products. Schneider microcomputer PLC control, Schneider intelligent touch screen, change specifications, filling volume adjustment, parameter setting, automatic cleaning, manual operation, etc. are evenly completed on the touch screen.

The self-developed floating ball optoelectronic feeding system not only ensures the automatic feeding function in the filling process, but also solves the problem of frequent feeding errors in the filling machine industry.

Our original weighing pump-type pressurized double-speed filling, this technology has far surpassed similar products in the same industry, allowing users to experience faster and accurate filling.

Photoelectric sensing and pneumatic door control, lack of bottles, inverted bottles are automatically protected.

---------------------------------------------------------

The main technical parameters:

Filling range : 100mL-5000mL

Filling accuracy : ±5g (4L)

Gas working pressure: 0.6-0.8Mpa

Motor power: 1KW

Power supply voltage: 380V/220V 50/60Hz

Machine Size:2000mm X1270mm X 2450mm

---------------------------------------------------------

FAQ

<1> How can I ensure that I get the high-quality machine?

As a manufacturer factory, we are looking for long-term cooperation, not one-time business, we have a strict supervision and control of every manufacturing step from raw materials purchasing, brands choosing to parts processing, assembling and testing. After testing the whole processing of the machine operation until everything is ok, then we send the goods to our customer.

<2>How about the Warranty and "Quality Assurance"?

We offer 12 months maintenance period to the problems that caused by our design, manufacture, and material quality, and offer the relevant parts and effective services for free with the first time shipping and if the problems was caused by above reasons. We will offer a life-long technical after service support for customers.

<3>How about the installation & adjustment?

After the equipment arrived at the customer’s site, customers responsible for unpacking and arranging the equipment in reference to the placement drawing or under our install-adjust technicians’ guidance. Operation manual and video demonstration sent along with the machine to give instructions. We have Chinese & English operation touch screen. Besides, we have professional after-sale group to customer's site to solve any problems. Costs of our staffs are decided at last.

<4> Could I have some spare parts of the machines?

We will send extra spare parts and accessories (such as sensors, motors, gaskets, tools, piping and so on) with the goods packed shipping together. Non-artificial damaged spares will be sent freely and shipping free during 1 year’s warranty.

<5> Are There Training for Customers?

We are responsible for offering the technical training to user. The training content includes the structure and maintenance of the equipment, control and operation of the equipment. Through training, users' technical staff can grasp and the skill of operation and maintenance proficiently, and deal with the general troubles in time. We will appoint qualified technical staff for the guidance.

<6>Could we customize the production line and machinery?

We can customize base on the factory size of our customers’ needs base on the volume of production. You could let us know your factory size drawing; we can do production & machinery design, tank and pipeline welding construction, automatic central control blending system, automatic heating system, filtration system, automatic filling system, automatic three-dimensional storage system, automatic anti-counterfeiting traceabilitysystem.