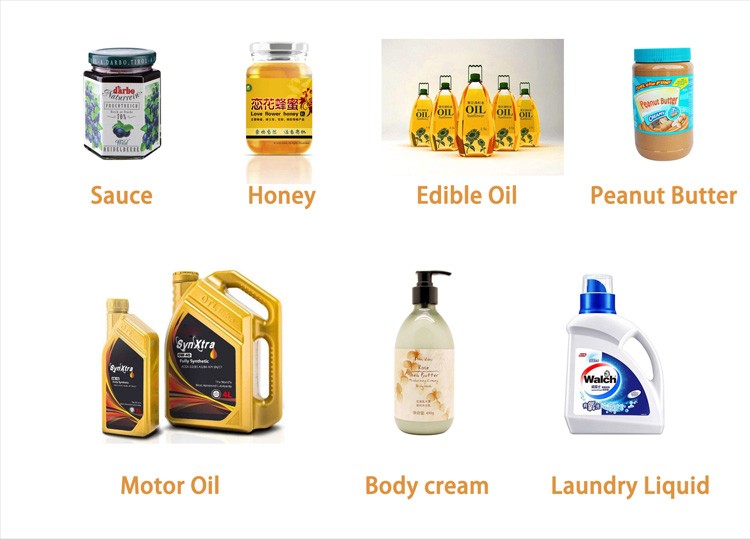

This Volumetric Piston Fillers are widely used by industries in the Food & Beverage, Personal Care, Cosmetics, Agricultural, Pharmaceutical, Animal Care and Chemical fields.

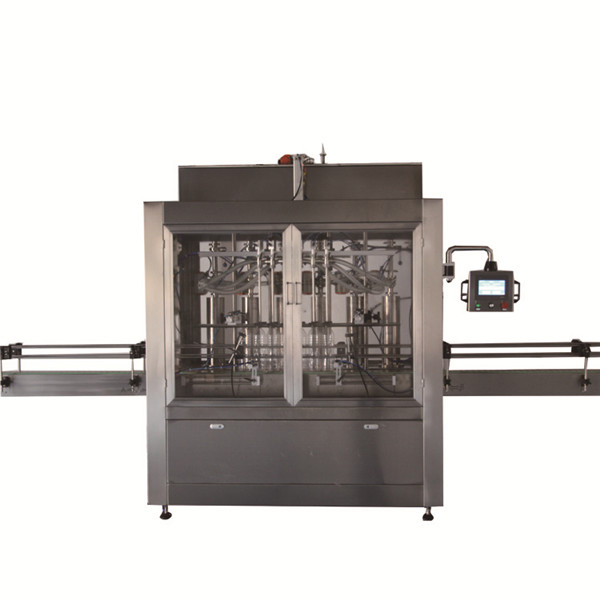

How it works:

This series of filling machine is for the automatic piston filling machine. Through the cylinder to drive a piston to draw and put out material, and then with a one-way valve to control the flow of material.With a magnetic switch to control the cylinder stroke, you can adjust the filling volume.

Performance:

This automatic piston filling machine is based on the original series of filling machine, through the introduction of advanced filling machine technology at home and abroad, and make a series of transformation and innovation, Thereafter its structure is more simple and reasonable, with a higher accuracy in filling. Parts in contact with the material is made of 304 stainless steel and conform to GMP requirement. Pneumatic components are applied with Germany FESTO, Taiwan Airtac, SHAKO and other metal control pneumatic components. The sealing parts are made of polytetrafluoroethylene material and silica gel material, with corrosion-resistant, anti-aging, high temperature, good sealing, etc. It is suitable for the food, pharmaceutical, chemical, cosmetic, oil, pesticides and other industries as ideal filling equipment.

Product Features

- Operation: Control Panel.

- Semi Auto/Continuous Operation Selector Switch.

- All Parts in Contact with Product are Food Grade.

- Stainless Steel Construction.

- Rugged Rotary Valve System Design.

- Silica gel O-ring System.

- Piston Feed Speed Adjustment.

- No-drip Option Included and Installed.

- Easy to Clean and Maintain.

- Sanitary Stainless Steel Quick Disconnect Fittings.

- Easy to Operate.

- Quick Connect/Disconnect Pneumatic Fittings.

- Pneumatic Operation.

- With the Air pressure gauge,Adjustment Piston Volume Adjust.

- Air Intake Pressure.

- Air Consumption 3-5KG 0.4-0.6MPa.

Technical Data

- Power supply voltage: 220v

- Power: 10w

- Filling volume: 100-1000ml

- Filling head: double head

- Rated air pressure: 0.4-0.6MPa

- Filling speed: 20-60 bottles/min

- Filling accuracy: ±0.5%-±1%

- Weight: 44kg (96.8lb)

- Speed: Approximate 2-50 r/min

- Accuracy: ≤±1%

- Machine size: 1150×680×550mm (45.26"×17.98"×21.65")

- Package size: 1160×550×335mm (45.67"21.65"13.19")

Package

- 1×Main Unit

- 1×English Instruction Manual

- 1×Packing List

- 1×Product certification

- 1×Set of hexagon wrench(1.5,2.5,3,4.5)

- 1×Set of Sealing ring (O type, planarity)

- 1×"+"screwdriver

- 1×"-"screwdriver

Safety Precautions:

- Use the power supply and gas source in accordance with the provisions, you must maintain the stability of the gas source in a continuous working condition and it can not be too high and too low. (The pneumatic explosion-proof filling machine is used without power. )

- Before disassembling or servicing the unit, It be sure to turn off the air supply and power.

- The rear half of the machine (near the control button) and the lower part of the rack, equipped with electrical control components. No matter under what circumstances can you not directly flush the main body, otherwise there will be electric shock hazard, damage to electrical control components.

- To prevent electric shock, the machine have a good grounding device, please equip the machine with a grounded power outlet or directly on the machine body grounding settings.

- After turning off the power switch the machine electrical control part of the circuit there is still voltage. when controlling circuit fault repair, please be sure to unplug the power cord.

- Your eye shall not get close to the filling head in the course of work, and pay attention to personal safety.

- You can not put hand on the cylinder central axis in the course of work, pay attention to your hand.

- It is best to use the detergent first to clean the machine in the use of materials before filling, and use clean water to clean-up, so as to avoid oil or outside material mixing, resulting in waste of materials and damage to the machine.

Work is affected by the following factors:

- Factors affecting the accuracy of the filling: hand compressed air stability, material uniformity, filling speed.

- Factors that affect the speed of filling: the viscosity of the material, the size of the cylinder, the nozzle size, the operator's proficiency.

- The machine has two ways, foot switch filling and continuous automatic filling, two filling methods can be arbitrarily switched. Initially recommended to use foot switch filling.