The Scope of Application

The model top surface labeling machine suit for box, carton, bags, container, cups and so on.

Equipment function characteristics

1) Control system: German SIEMENS PLC control system, with stable operation and extremely low failure rate.

2) Operation system: German SIEMENS 7 inch touch screen, directly visual interface easy operation, with Chinese and English language, also rich with help function and fault display function.

3) Labeling system: The whole labeling engine use German Avery brand , only SKILT with this kinds labeling engine in China, with rather high Competitive Advantage;

4) Alarm function: Such as label spill, label broken or other malfunction during machine working all will alarm and stop working.

5) Machine Material: Machine and spare parts all use material S304 stainless steel and anodized senior aluminum alloy,with high corrosion resistance and never rust.

6) Others: Low voltage circuit all use the German Schneider brand. The bearing use IKO .

Technical Paramter

| Driving Mold | German Avery |

| Capacity (Pcs/min) | (20-200pcs) Depends on bottle and label size |

| Conveyor Speed(m/min) | ≤35m |

| Label material | Adhesive sticker, transparent or opaque |

| Suitable label size | Width:15-160mm Length:15-300mm |

| Suitable bottle size | can customized |

| Voltage | AC110V/220V/380V |

| Operating direction | left or right |

| Labeling accuracy | ±1.0 mm |

| Total power | 550W |

| Machine size | 1800x800x1600mm |

| No | Name | Unit | Brand |

| 1 | PLC control system | 1 set | SEMIENS |

| 2 | Touch screen | 1 set | SEMIENS |

| 3 | photoelectric sensor (check bottle) | 1 set | Japan KEYENCE |

| 4 | Photoelectric sensor (Check opaque label) | 1Set | German Lueze |

| Photoelectric sensor (Check transparent label) | 1Set | USA Lion | |

| 5 | Labeling engine | 1 set | German Avery |

| 6 | Drive | 1set | German Avery |

| 7 | Main transport motor | 1 set | German JSCC |

| 8 | Separate motor | 1 set | German JSCC |

| 9 | 9 Speed Controller | 1 set | German JSCC |

1. The machine mainly uses SUS304 stainless steel and aluminum alloy (sandblasting anodizing) material.

2. The host is driven by advanced servo system, with high speed and high positioning accuracy.

3. Optoelectronic products are imported famous brands, with high stability and accurate detection.

4. PLC with man-machine interface control, operation is concise and clear.

5. The host position can be flexibly adjusted on the top, bottom, front and rear, parallelism and verticality.

6. The speed of conveyor belt can realize digital adjustment of touch screen.

7. The device can operate independently and can also be connected to the production line.

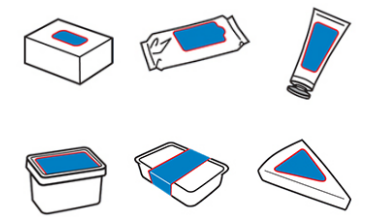

Flat labeling machine

Apply to all kinds of flat product labeling. (for example, paper card, self sealing bag, carton, food box, medicine box, cosmetic box, stationery, CD CD, card, electric board, all kinds of oil kettle, etc.)

Technical parameter:

| Machine model | Flat label machine |

| Machine size | 2000(L)×700(W)×1600(H) |

| Labeling speed | 30-200pcs/min(Depending on the size of the bottle and the length of the label) |

| Object height | 30-200mm |

| Object thickness | 20-200mm |

| Label height | 5-180mm |

| Label length | 20-300mm |

| Labeling accuracy | ±1mm(Not calculate the error of bottle and label) |

| Scollinner diameter | 76mm |

| Scollouter diameter | 350mm |

| Power supply | 220v 50/60hz 0.75Kw |

| Machine weight | 180kg |

Main Features:

1. The machine mainly uses SUS304 stainless steel and aluminum alloy (sandblasting anodizing) material.

2. The host is driven by advanced servo system, with high speed and high positioning accuracy.

3. Optoelectronic products are imported famous brands, with high stability and accurate detection.

4. PLC with man-machine interface control, operation is concise and clear.

5. The host position can be flexibly adjusted on the top, bottom, front and rear, parallelism and verticality.

6. The speed of conveyor belt can realize digital adjustment of touch screen.

7. The device can operate independently and can also be connected to the production line.

Packing & Delivery

| Packaging | |

| Size | 2900(L)×1800(W)×1650(H) |

| Weight | 550kg |

| Packaging Details | *Outside Packing: Standard wooden cases *Inside Packing: Stretch film wrapped up * Packaging according to client's requirements. |

Our Service

1.Warranty time: Two years,from the date which the product is qualified commissioning Any damage except the wrong operation during warranty period is repaired freely. But the travel and hotel expenses should be count on buyer.

2.Commissioning services: The product's installation and commissioning at the demand side,our engineers will not leave there until get your agreement.

3. Training services: our engineers will train your staff to operate it during the period of installation and commissioning,they will not leave there until your staff can operate it properly and normally.

4. Maintenance services: Any malfunction happened,once you enquiry us,we will .reply you within 48 hours except the special reasons.

5. Lifelong services: We provide lifelong services for all the products we sold out,and supply the spare parts with discount price.

6. Certificate services: We can provide related certificates to customers freely according to the request of customers.

7. Inspection services: You can ask the third part inspection company or your inspector to inspect the products before shipment.