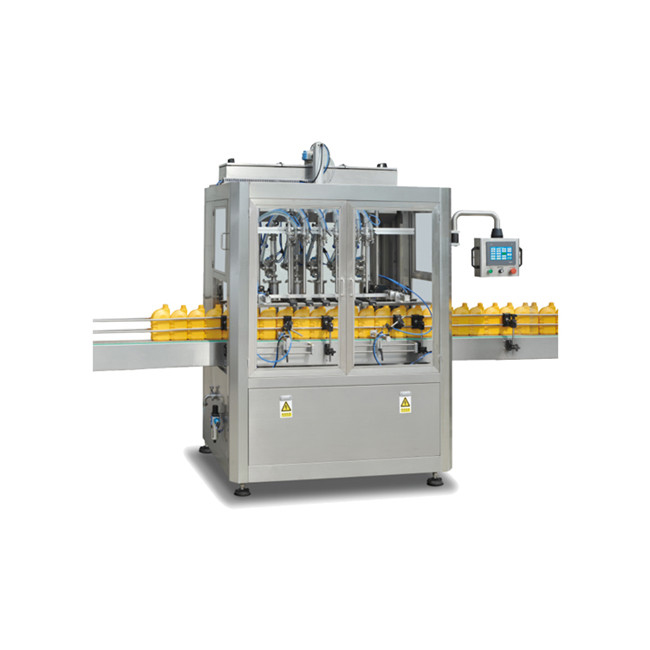

Oil filling machine is for 1-5L bottle chemical and oil packing, the machine combines filling and capping, it can fill the

bottled cooking oil, jams, chili paste, sauces, and other high viscous liquids. The food and oil packaging production line can process different bottles holding less than 5L and functions as a complete production line with conveyors, labeling, filling, sealing, and packaging into cartons.

Filling Machine, Capping Machine, Labeling Machine.

Pouring heads | 10 heads |

Production speed | ≤3600 bottles/hour |

pouring volume | 200ml-1000ml |

Measure precision | ±1% |

Contour sizes | 2000*1000*22000mm |

Machine Weight | 850KG |

3.Filling speed: instead of the traditional power delivery -- pressure artesian flow, adopting frequency converter to adjust the speed of filling,the efficiency highly raised. The speed can be arbitrarily adjusted on panel.

4.The adjustment of filling accuracy, promoted by our company, the weight of filling can be set on the touchscreen.The equipment carries on automatic conpensation system when error occurs.

5.Each filling head’s speed of machine can be set on touchscreen.

6.Conveyor belt be adjusted by frequency conversion

Machine details

2. Oil filling machine is precise with a high qualified rate. Production capacity can be increased by up to 30%.

3. Double-sided self-adhesive labeling machine processes round and flat bottles.

4. Falling style packaging machine can process small quantities of heavier bottles that other machines can't.

5. The automatic carton opening and sealing machines are easy to operate and speed up production.

A1: We are a manufacturer with more than ten years; we supply the factory price with top grade quality, and welcome to visit our

factory.FAQ

Q2: What’s your guarantee or the warranty of the quality if we buy your machines?

A2: We offer you machines with 2 year guarantee and have engineer can go overseas supply life-long technical support.

Q3: When can I get my machine after I paid?

A3: The deliver time is based on your order, for general about 1-3 month.

Q4: How can I install my machine when it arrives?

A4: We will send our engineers to your factory to install the machines and train your staff how to operate the machines.

Q5: How about the spare parts?

A5: We will offer you a spare parts list for your reference, and will provide all parts when you need them.