This machine used primarily for thick viscous liquids and/or particulated products with limited changeovers. Examples include liquid soaps, cosmetics and heavy food sauces where positive displacement or high-pressure filling is required. Also excellent for volumetric filling of expensive products where high accuracy is needed. Higher capital cost but even small machines can produce very high output.

1. Used for filling, cap-locking, mouth sealing work of plastic or glass bottles.

2. Used for filling and mouth sealing work of oral agent, external use agentia, cosmetics, food and beverage and other industries.

3. It can meet the need of higher output with adopting two-rail bottle feeding, two-rail filling and two-nozzle cap screwing or rolling and pressing. This machine has high filling accuracy and can be disassembly and sterilized conveniently, adopting quick-joint stainless steelpiston pump.With the use of constant torque cap screwing and pneumatic protector, sealed mouth is leakproof.

Applicable to food, daily chemical, cosmetic, oil and the other industries with relatively high demand for production capacity requirements.

2.Varying velocity of filling: It can be used to realize the slow filling through the varying velocity method during the whole filling when approached the specified filling capacity; so that it can be prevented liquid from spilling over the bottle to cause pollution.

3.Easy to adjust: The filling specification can be changed only by changing the parameters in the touch screen, and all the filling heads are changed in place one time.

4.Hygiene and convenience:The whole machine adopts the anti-leakage treatment; the steel cylinder adopts the quick installation connection, the maintenance is quick and convenient.

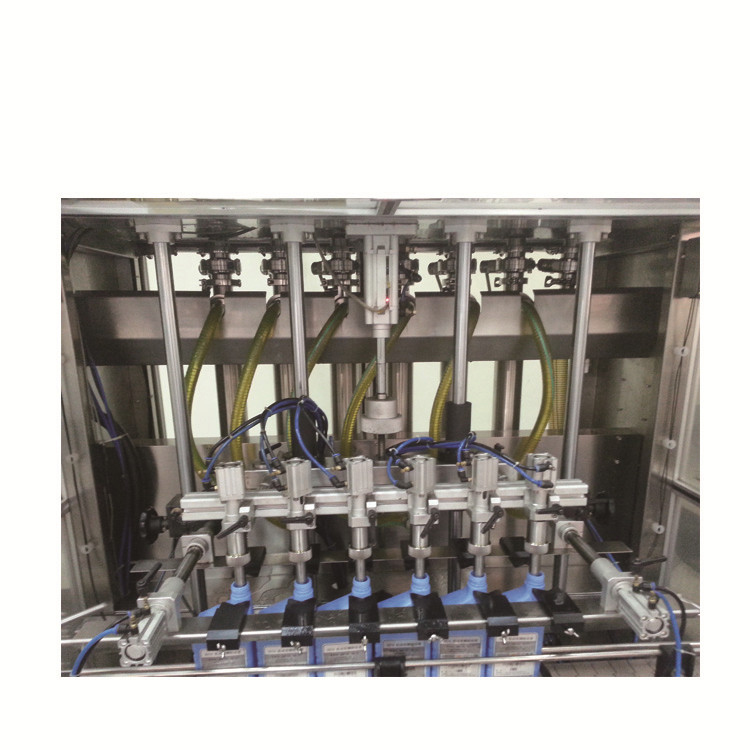

Filling head | 20 |

Production speed | ≤ 5000b/h (i.e.500ml) |

Filling volume | 50-1000 ml |

Dose accuracy | ±1% |

Air pressure | 0.6-0.8 mpa |

Bottle size | W 30-100 mm , H 50-260 mm |

Power supply | AC220V , 50/60hz |

Power | 2 kw |

Bottle mouth diameter | ≥18mm |

Machine size | 2440 x1200x2200mm (L X W X H) |

| Name | Brand |

| PLC | Schneider |

| Touch screen | Schneider |

| Main motor | Taiwan |

| Air parts | Airtac |

| Servo motor and driver | Panasonic or Schneider |

| Frequency converter | Danfoss |

| Low voltage components | Schneider |