This machine is applicable for circular surface labeling, Such as round container, the detail application description as following table:

| Issue | Application Description |

| Applicable Container | The following scenarios can be selected for one machine: 1) Round Container , such as round bottle 2) Circular surface, such as container with a section of circular arc |

| Applicable Type of Label | Self-adhesive Label 1) Non-transparent as the standard 2) Transparent as the optional |

| Number of the Label | 1) 1 label 2) 2 labels which printed on one label roll |

Following are the reference style of containers:

Standard Features

• Suitable for round container , or container with a section of circular arc , signal or double labeling

• Stainless Steel 304 and High class aluminum alloy as the construction of the machine

• Unique labeling heads enable the label’s tightening and tension more steady. And assure the labeling accuracy.

• The professional labeling device enhances the quality of the labeling. To ensure no wrinkles and no bubbles. And tightness of the overlapping.

• Calibration scales are convenient device for the contain shape adaption

• PLC and Touch screen HMI control to achieve intelligent operation and trouble shooting

• Intelligent control, automatic photoelectric tracking, with no object no labeling, no label auto-correction

Optional Features

• Transparent labeling detecting sensor

• Code bar online printing

According to the PLC parameter setting through touch screen HMI, the container from the upstream process , through the conveyor. Pass the container separating wheels,. Sychonize with container and labeling detecting system, the container get accurate labeling by the labeling heads. The labeling reinforcing device will ensure the labeling quality as the final step.

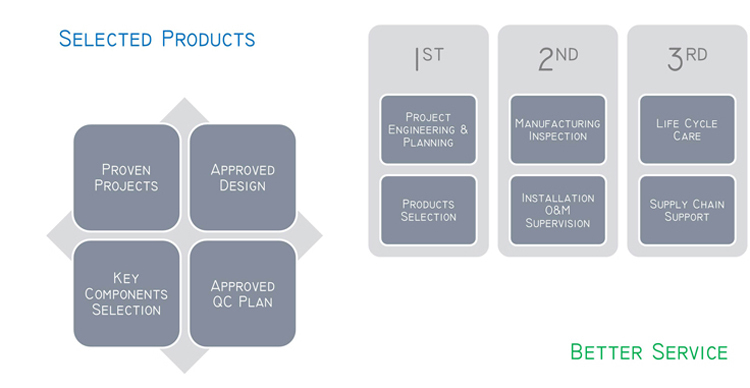

Except for the design of the machine, the key components configuration will determine the quality of the machine or system, below is the shortlist configuration of the key components:

| No | Components | Material / Short List |

| 1 | Programmable Logic Controller | Delta, Siemens, Mitsubishi, Panosonic |

| 2 | Touch Screen | Weinview, Siemens,Delta,Kinco, Panosonic |

| 3 | Stepper/Servo Motor | Teco, Delta, Panosonic,Leadshine |

| 4 | Frequency Convertor | Delta, Schneider,Leadshine |

| 5 | Key Electric Components | Schneider,Chint, Ls, Ark |

| 6 | Key Protection & Relay | Schneider,Delixi |

| 7 | Cylinder, Filter | Airtac , SMC |

| 8 | Photocell Sensor | Autonics , Keyence, Leuze, Panosonic, Datalogic |

| Catalogue 1J-x-xxxxx | T-21100 | |

| Control Method | Automatic | |

| Number of Label | 1 as the standard , or 2 labels which printed on the same label roll | |

| Transparency of Label | Non-Transparent | |

| Adhesive | Self-Adhesive | |

| Coding/Printing Machine | Exclude | |

| Width of Label | 15-150 mm - Include the back paper | |

| Length of Label | 20-340mm | |

| Labeling Speed | 30-80 pcs/min for normal motor 40-120 pcs/min for servo motor | |

| labeling Tolerance | +/- 1mm | |

| Diameter of Container | 25-100 mm | |

| Roller Outer Diameter | 280mm-Max | |

| Roller Inner Diameter | 76mm | |

| Standard Speed | Servo motor : 5 ~ 25m/min Stepping motor : 5 ~ 19m/min | |

| Compress Air Required | Not Applicable | |

| Air Consumption | Not Applicable | |

| Power Requirement | AC 220V 50/60HZ | |

| Electricity Consumption | 0.53Kw | |

| Approximate Weight ( Net) | 185 kg | |

| Dimension ( ‘mm ) | 1950*1100*1300mm | |

Practically, compare with the simple machine in the market, we are more focusing on the details, the advantages as indicated in the following table:

| Labeling Target | Our Design |

| No wrinkles | Reasonable label guiding device, include a) Label guiding and pulling b) Label tension maintaining , c) label separating processes |

| No bubbles | Reasonable labeling and Reinforcing devices |

| Accurate labeling | a) High quality and position adjustable label detecting sensor b) Container positon adjustment device c) Labeling synchronization control |

| Flexible operation | a) Pedal Control / Automatic Detecting b) Single or double labels c) Code printing can be integrated d) Flexible programming by PLC e) Necessary protection, like short circuit , overload etc |

In ordr to enable you understand our products conveniently , following documents are available, but not limited, to be provided upon the stage of purchasing

| No | Document | Code | Description |

| 1 | Products Selection Guide | SG | To select or customize the suitable products for the clients upon the feedback of Selection Guide, which include project background, parameters and other client’s requirement |

| 2 | Products Profile | PP | To enable the clients understand the overview of the products, Covers sections of Basic Features, Application, Construction, Typical Products, Approvals, and Optional Features |

| 3 | Installation Instruction | IN | To explain the step of installation of the equipment, and include commissioning instruction as well |

| 4 | User Manual | UM | To cover the content of Operation & Maintenance and Trouble Shooting |

Customization Philosophy

The product demonstrating may not perfectly meet your requirements, our philosophy is to customize your real need, To minimizing idle capacity and function. To supply you performance and cost balanced products. Following are the factors shall be taken into account during customization:

• Transparent labeling detecting sensor

• Code bar online printing

Selection Guide

Selection Guides are available for circulation, contact us to get products selection and customization support.

Statement

- The pictures demonstrating in this profile represent products of range, and subject to the newest or customized design

- Due to the huge number of documentation updating, the data indicated in this profile may not be updated timely, Please contact with our customer service for newest version.

- The features or functions appear in this profile subject to the additional description of quotation