I. Introduction

The machine introduces the advanced technology , can complete bottle feeding, cosmetics filling, aluminum foil sealing and cap screwing automatically. The caps are put on automatically.

It adopts the double-slope cover-punching technology and largely developed the foil usages.It adopts the integral motor design the first rate driving, so the running is steady and flat. With the reasonable design, KPGX style filling and capping machine is widely used in pharmacy, food, cosmetics industry.

II. Features

1. The filling system is applied with the piston pump system, which has a high filling precision and a large dosage range.

2. The filling system is heat-resistant and corrosion resisting. It has an overwhelming advantage when the material has a corrosive feature.

3. Filling system is equipped with a sensor. If no bottle detected, the filling will not work. It prevents the material from being wasted.

4. The filling nozzle goes down to the bottom of the bottle for filling, preventing bubbles, especially for cosmetics.

5. The machine is installed with a low level storage hopper which makes the cleaning and disinfection easier.

6. The capping system is linear, which is very convenient when there are different kinds of caps.

7. In the capping screwing system, all parts in touch with the caps are covered with a soft silicon gel. And it saves the caps from being scratching.

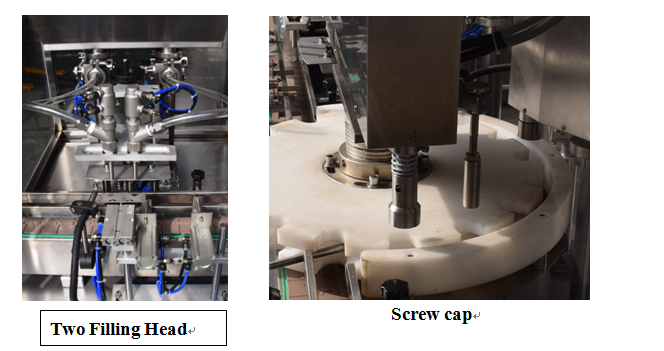

8. Claw design head-screwing design which is easy to adjust the tightness, and no need to make a new cap moulds when the cap is changed.

9. The ready-packaged connection is the main connection method which makes the assemble and dissemble very convenient.

10. It is applicable to all kinds of viscous and non-viscous liquids

11. The whole system is controlled by PLC. The touch screen make the operation simpler.

12. For the conveyor, we have plastic chain type and belt type for customer’s option. Plastic chain is easier to clean. Belt type is soft and makes no harm to bottles.

13. The most part of the machine is made from SS304. For special material, the contacting part is SS316L, which is able to reach the GMP standard.

14. The filling & capping machine can equipped with a dust cover to make it more sanitary (optional).

III. Technical Parameter

1. Filling head: 1

2.Filling range: 5ml~200ml

3. Filling precision: ±0.5%

4. Filling capacity: 20-30pcs/min

5. Hopper size: 30L (customized)

6. Power supply: 220V/ 50Hz/ 1phase

7. Power rate: 2 KW

8. Air consumption: 0.6~0.8MPa

9. Size: 2400mmx850mmx1650mm

10. Weight: 450kg

Packaging & Shipping

We are using standard export plywood cases. To ensure that the transport process will not damage and safety arrived in customers' hands.

We are specializing in machinery including,

Pharmaceutical industry,

Food industry,

Chemical industry,

and provide customers with material, etc

Meanwhile, we can undertake turn key projects for conceptual design, process design, water treatment solutions, clean-room design, etc.

Because we stick to offer the high quality and competitive price to our customer, our machines have been exported many countries of world

We have established business relationship with many directly customers and have many agencies from abroad.

We always stick to the principle that customers are the god, and quality is the first. Therefore, we stick to do all activities as per user’s demands.

Customer service including technical support, installation & commissioning after sale.

Welcome all of friends from abroad to our company and establishing good business cooperation.

Our Services

Installing and Commission:

We will install and test the machine in best working condition before shipment. If customer requires our technician to adjusting the machine and train technician at arrival place, we will send technician there. All our expenses including round-trip air ticket to the nearest airport, local conveyance to your factory, Lodging&Boarding expenses shall be payable by you. In case the stay of our technician, additional service fee will be charged .

Warranty period:

One year for fully machine guarantee. And in this year if the machine broken caused by mechanical problem, all of the spare part is free. The service of the machine all though the machine’s life.